At Dynequip, we support a variety of food processing plants. One of our favorites is coffee. After all coffee is what helps us make it through the days! Our creative approach to building and augmenting food processing systems has helped local and national coffee brands. We are proud of how our systems help bring excellent brews to the masses.

Some of the most common systems we help our clients with include:

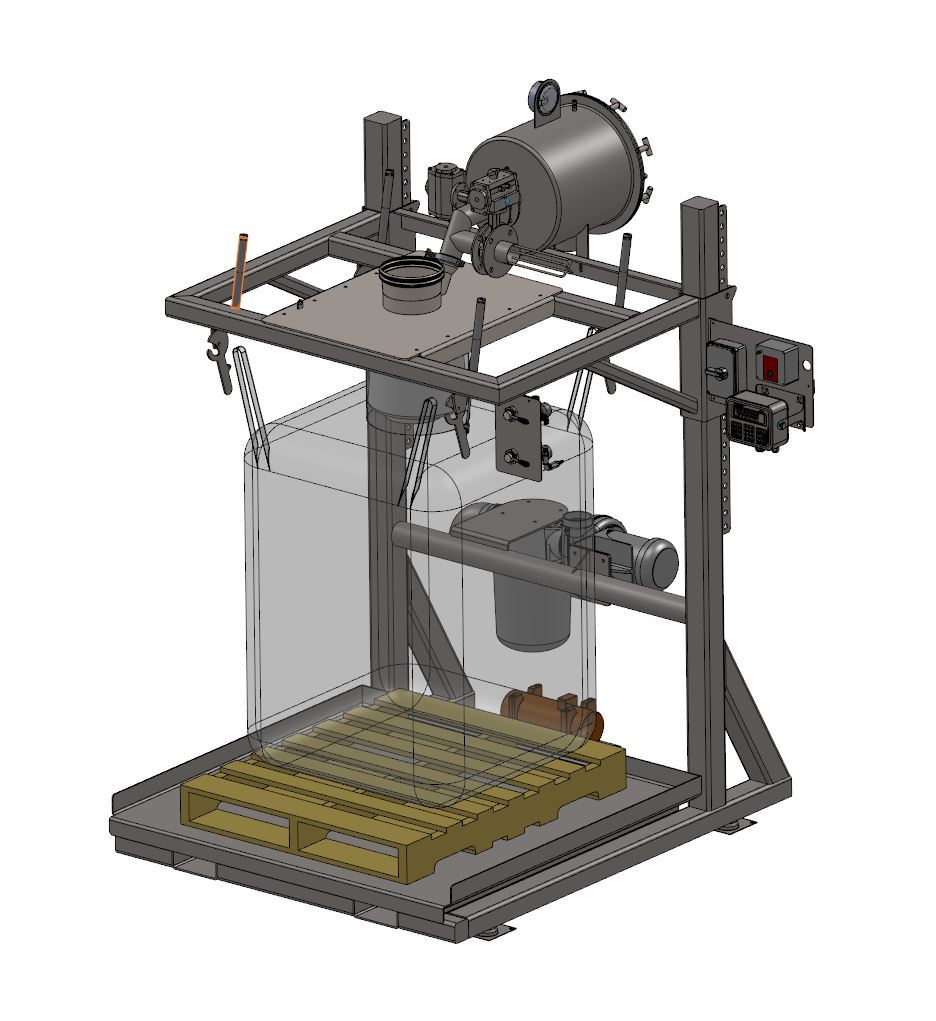

Bulk bag loading and unloading

Super sacks are a big deal (literally) in the coffee world. Loading and unloading these heavy sacks can be physically taxing and an opportunity for on-the-job injuries. In a recent build (see photos) below, we created super sack unloading system for a client to improve efficiency and reduce injury risk. As you can see, we can provide 3D drawings to show our client exactly what we have in mind before moving the next phases of building. We love to see how the drawing comes to life in the images below.

Conveying of Delicate Materials

Tubular drag conveying systems are used to move the unloaded beans to the plant’s grinders or roasters. Depending on the production requirements, the beans may need to be conveyed delicately so they do not break. Cablevey is a perfect solution for moving delicate commodities from one point to another within the processing system.

Portable Conveying

Portable flex auger systems are designed to fit into any part of the process with custom hoppers and a pivoting arm. This system is commonly used to move the coffee in ground or whole bean state to the roasters or grinders.

USDA Sanitary Systems

When working in the food industry we incorporate USDA guidelines into our builds. From stainless steel equipment to HEPA filtration systems, we offer the best equipment at the highest standards.

As experts in the above systems, Dynequip can help you maximize your productivity in processing coffee or any other food related industry.