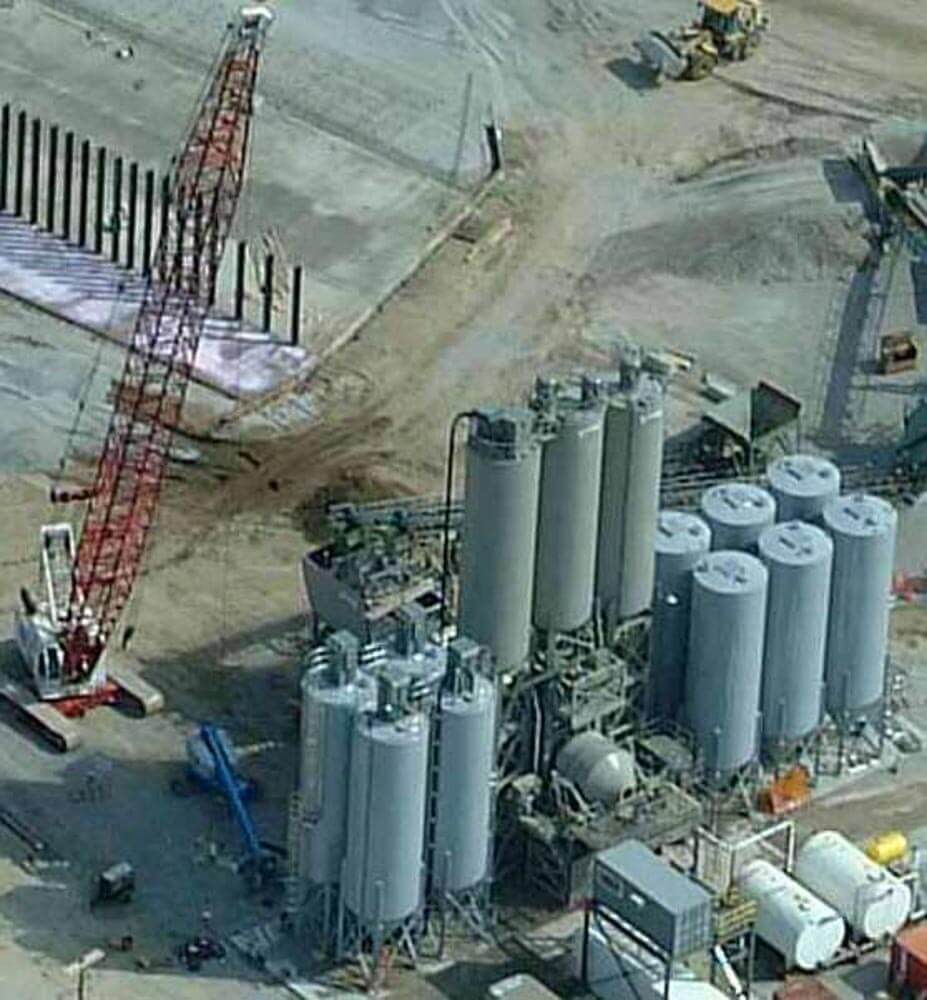

Silos or storage tanks for even the most demanding specifications

We serve a wide range of industries around the world. We have supplied tanks to virtually every manufacturing and processing industry. In fact, chances are we’ve met the demands of a storage challenge similar to yours before.

Carbon, stainless steel, aluminum, and a number of specialty alloys are available to meet the unique needs of any industry. Units can feature an enclosed, skirted bottom ideal for keeping equipment safe from the effects of weather. They can also specialize in factory- and field-welded storage tanks for virtually any dry bulk material and a wide variety of liquids.

Since 1971, Dynequip and has been meeting and exceeding the storage requirements for all types of industries including:

- Food Processing and Milling: raw grains, flours, and by-products.

- Cereals: whole and processed grains, sugar, additives, and by-products.

- Bakery: flour, sugar, spices, salt, oils, additives, and other ingredients.

- Chemical: storage and blending of dry bulk solids; storage of liquids.

- Foundry and Basic Metals: raw material storage for metals, ores, chips, and by-products; all types of sand, clays, resins, and binders.

- Mining and Aggregates: sand, gravel, cement, asphalt, rock, roofing granules, and minerals.

- Plastics: storage and blending of pellets, powders, resin, and flakes.

- Power Plants: fly ash storage, waste treatment, coal hoppers, and bunkers.

- Pulp and Paper: storage of wood chips and chemicals; waste treatment.

- Waste Treatment: storage tanks, complete assembly of systems and vessels for lime, soda ash, carbon, and water treatment media; vessels for processed sludge.