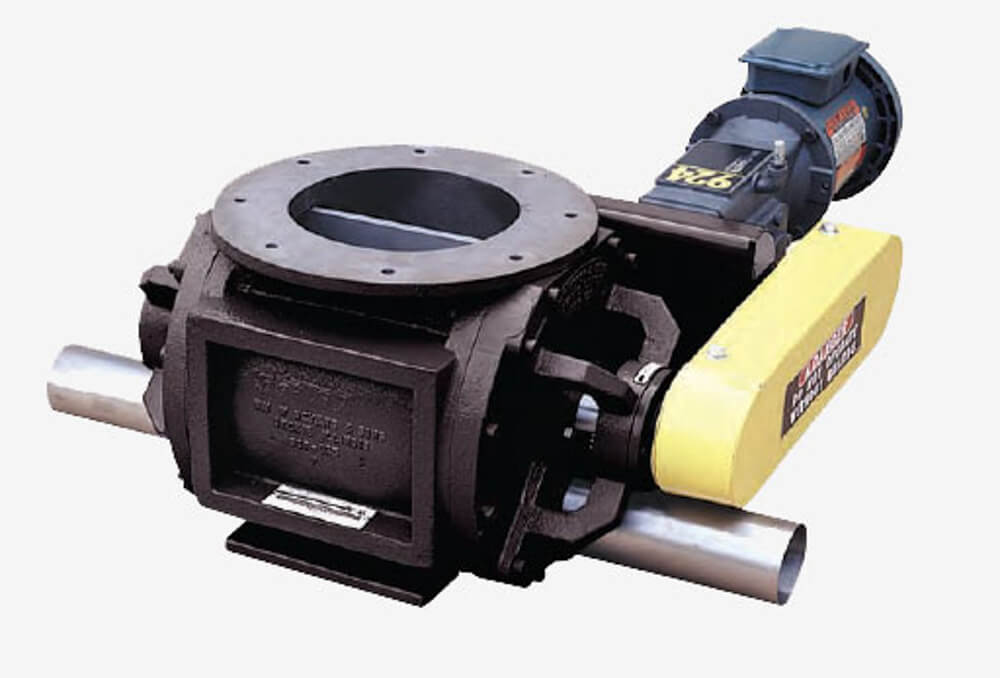

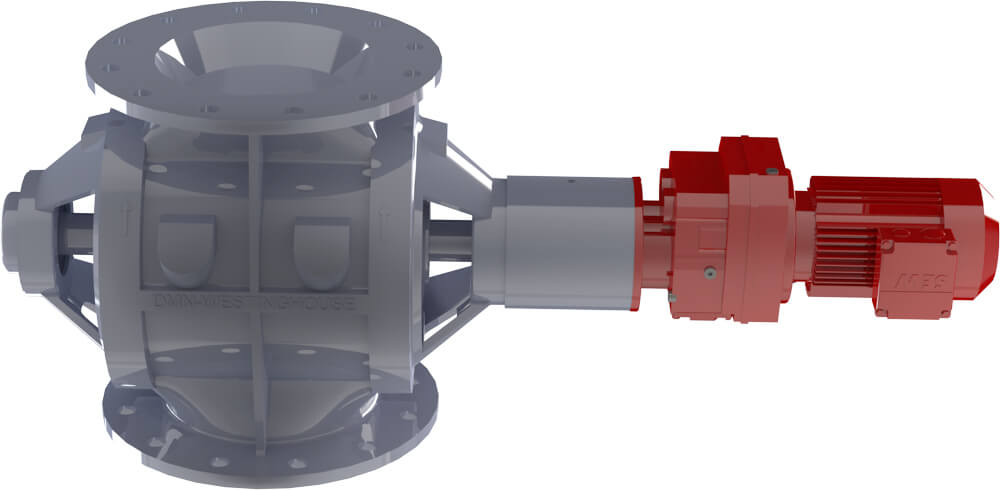

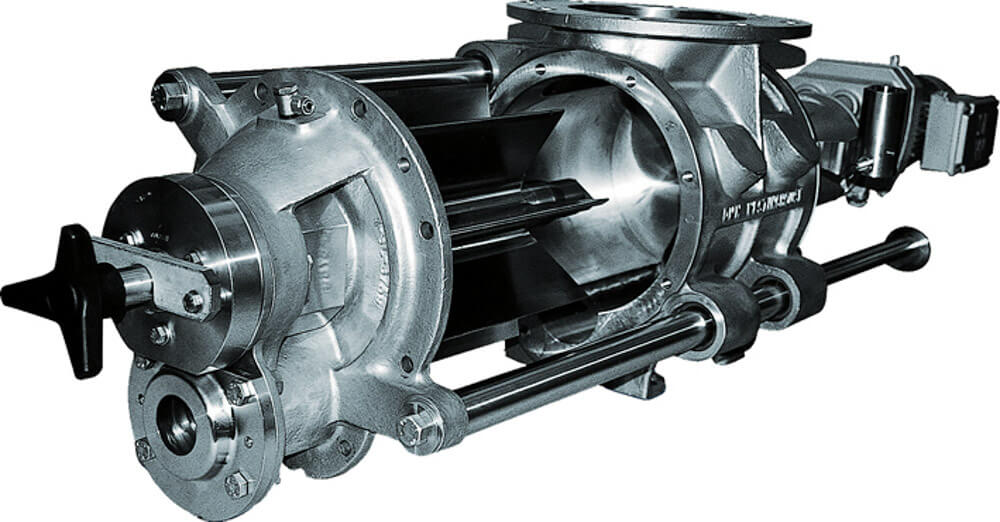

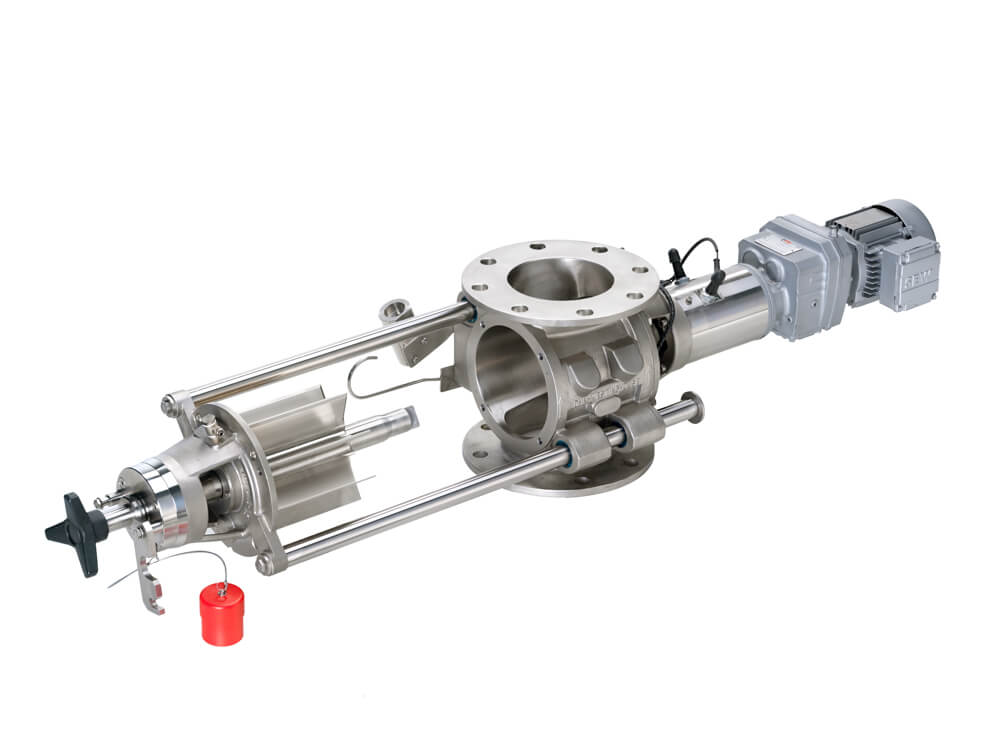

Rotary valves, also known as rotary feeders, are commonly used in industrial applications as a component in bulk or specialty material handling systems. The basic use of the rotary airlock feeder is as an airlock transition point that seals pressurized systems against loss of air or gas while maintaining a flow of material between components with different pressures. Rotary feeders are primarily used for discharge of bulk solid material from hoppers/bins, receivers, and cyclones into a pressure- or vacuum-driven pneumatic conveying system. Components of a rotary feeder include a rotor shaft, housing, head plates, packing seals, and bearings. Rotors have large vanes cast or welded on and are typically driven by small electric motors.

Airlock Applications

Airlocks have a wide application in industry wherever dry, free-flowing powders, granules, crystals, or pellets are used. Typical materials include cement, ore, sugar, minerals, grains, plastics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, etc.

Pollution Control

Rotary valves are ideal for pollution control applications in wood, grain, food, textile, paper, tobacco, rubber, and paint industries; the Standard Series works beneath dust collectors and cyclone separators even with high temperatures and different pressure differentials.

Types of rotary valves

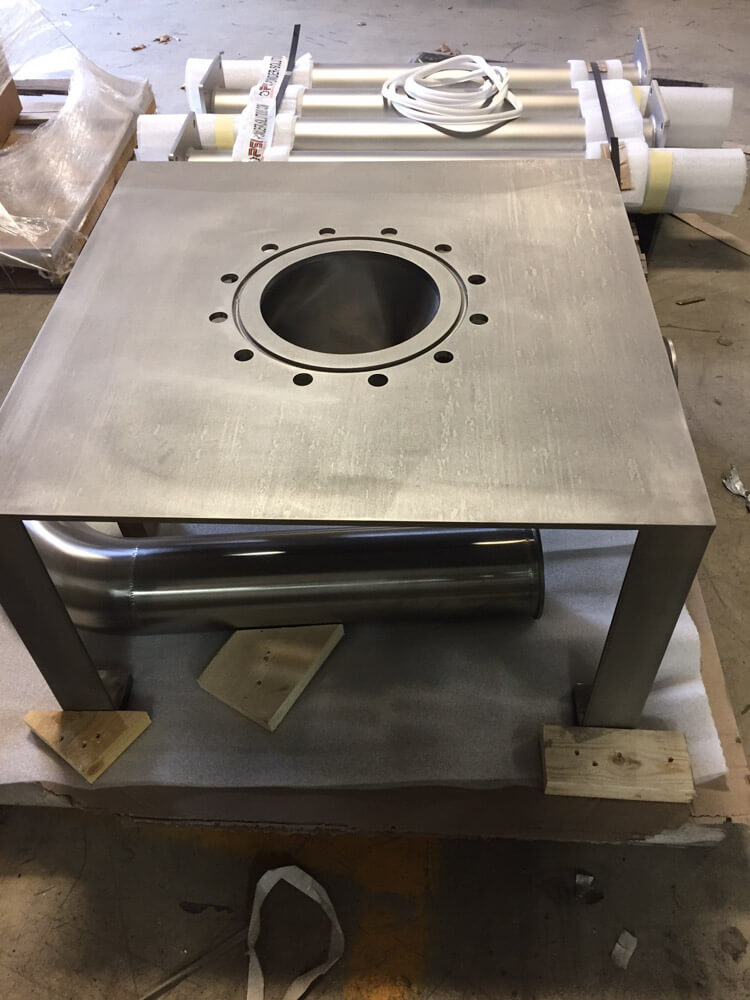

Rotary valves are available with square or round inlet and outlet flanges and drop through or blow through designs. Housing can be fabricated out of sheet material or cast. Common materials are cast iron, carbon steel, 304 SS, and 316 SS. Rotary airlock feeders are available in standard and heavy-duty models—the difference being the head plate and bearing configuration. Heavy-duty models use an outboard bearing in which the bearings are moved out away from the head plate. Housing inlet and discharge configurations are termed drop-through or side entry. Different wear protections are available such as hard chrome or ceramic plating on the inner housing surfaces. Grease and air purge fittings are often provided to prevent contaminants from entering the packing seals.

Options

Rotary valves have the option to be quick cleaned, sanitized, and inspected or given maintenance in a minimum amount of time without the use of tools or removal from service, thereby reducing downtime and increasing system production. The clean-in-place rotary feeder is a special purpose valve designed for areas where cross-contamination is a major concern and lengthy shut-downs for clean-out are cost-prohibitive; these are suited for dairy, pharmaceutical industries, food, baking, chemical, plastics, paint, and powder coating plants. It is ideal for batch mixing systems such as those handling different colored resins which demand regular cleaning between cycles.