At Dynequip, we specialize in customized food processing material moving solutions. Salt, sugar, and spices are used in many areas of the food industry, like meat processing, baking, dairy, and general food processing. Let’s go over some of the equipment that is specifically designed for the food industry:

Flex Augers/ Portable Flex Augers

When it comes to transferring powder and bulk solid materials, flex augers are very efficient because of their simple design. Their open helix, shaftless design is great for adding ingredients at any point in the process. They can be built to meet food-grade USDA sanitary specifications. Flex augers are typically 25’ or less, and multiple augers can feed into each other.

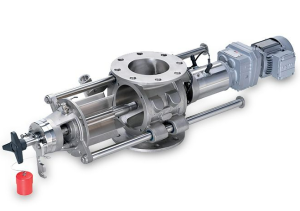

Rotary Airlocks

DMN Rotary Valves are used for metering products into the process or as an airlock to act as a barrier for potential explosions. Airlocks have a wide application in industries using free-flowing powders, granules, crystals, or pellets. This includes sugar, flour, coffee, and cereals. DMN offers NFPA-certified valves.

Rotary valves can be quickly cleaned and sanitized, increasing system production. The clean-in-place rotary feeder is designed for areas like the food industry where cross-contamination is a concern.

Bag Break Station

These are used to dump bags of material into the process manually. The bag dump stations can also have dust collection integrated into the system to help protect the operator and reduce material waste. All units are available in carbon steel with durable industrial finishes or in stainless steel with industrial or sanitary finishes.

Bulk Bag Unloader

Bulk Bag Unloaders are used to unload material from super sacks. The system is easily operated and effectively solves bulk bag handling operations. The unloaders are customizable, and we have many different configurations for our customers.

Feeders

Tecweigh offers a range of feeders that can tackle difficult materials as well as metering small amounts of ingredients into the process as needed. Loss-in-weight and volumetric feeders are a perfect solution for handling dry materials.

The experts at Dynequip will answer any questions you may have about what equipment would best support your company. Fill out a contact form on our website, and we will get back to you immediately!