Conveying fragile material can be a headache. If not done in an efficient, yet gentle way, you could lose a significant amount of raw material in processing.

Cablevey tubular drag conveyor systems are ideal for conveying delicate, fragile and specialty bulk materials through all phases of the production processes all the way to packaging.

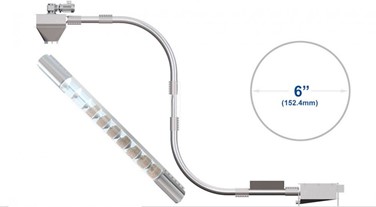

Using a combination of conveyance tubes with cables and discs attached at set intervals within the tubes, the design gently handles materials without blowing or forcing from inlets to discharges. Product loss is kept to a minimum by avoiding bumping, stress or friction breakage.

Another great feature of this conveyor is flexibility. Cablevey Conveyors are tube shaped and come in four different sizes ranging from 2 to 8 inches in diameter. These conveyors can be adjusted to different sweep angles to curve around different systems or obstacles. They can also be installed horizontally, vertically, and even diagonally to fit with existing systems.

Another great feature of this conveyor is flexibility. Cablevey Conveyors are tube shaped and come in four different sizes ranging from 2 to 8 inches in diameter. These conveyors can be adjusted to different sweep angles to curve around different systems or obstacles. They can also be installed horizontally, vertically, and even diagonally to fit with existing systems.

This 6” diameter conveyor shows how the product (in this case, coffee beans) is transported through the tube. The discs separate the material enough to avoid the product from breaking.

Cablevey Conveyors are also adaptable to your entire plant. By making small adjustments to the existing structures, these tubes can transport your material anywhere it needs to go. For example, if you have pet food pellets that need to be conveyed to the next room or building, you can easily do that with Cablevey. No matter where or what the conveyors connect to, it remains in a completely enclosed system to prevent contamination.

When it comes to cleaning the equipment, Cablevey can be equipped with various dry or wet cleaning processes. For dry cleaning, a brush box, urethane wiper, air knife, and sponge can be added to the conveyor to make cleaning simple.

- Brush box: When this is installed, the discs inside the tubes will pass through the brushes, which remove any dry debris from the cable and discs.

- Urethane wiper: This is a removable disc that is a little wider than the tube’s interior and acts as a squeegee to wipe debris off the side of the tube.

- Air Knives: When the discs pass through this cleaning section, the air knife blows off any debris stuck to the discs.

- Sponge: This is a clamp-on piece that can have cleaning products applied to it. It can rest on one of the discs and clean the interior of the tubes as the discs pass through.

The wet cleaning process includes a rinse, foam, second rinse, sanitize, and dry. Water and foam are sent through the tubes and clean all internal parts of the system.

To see how the Cablevey Conveyor is installed, watch this video: https://cablevey.wistia.com/medias/r7s7oiobbf

Dynequip is the Minnesota area’s exclusive representative for Cablevey. Dynequip has been providing conveying system solutions to our customers since 1971.