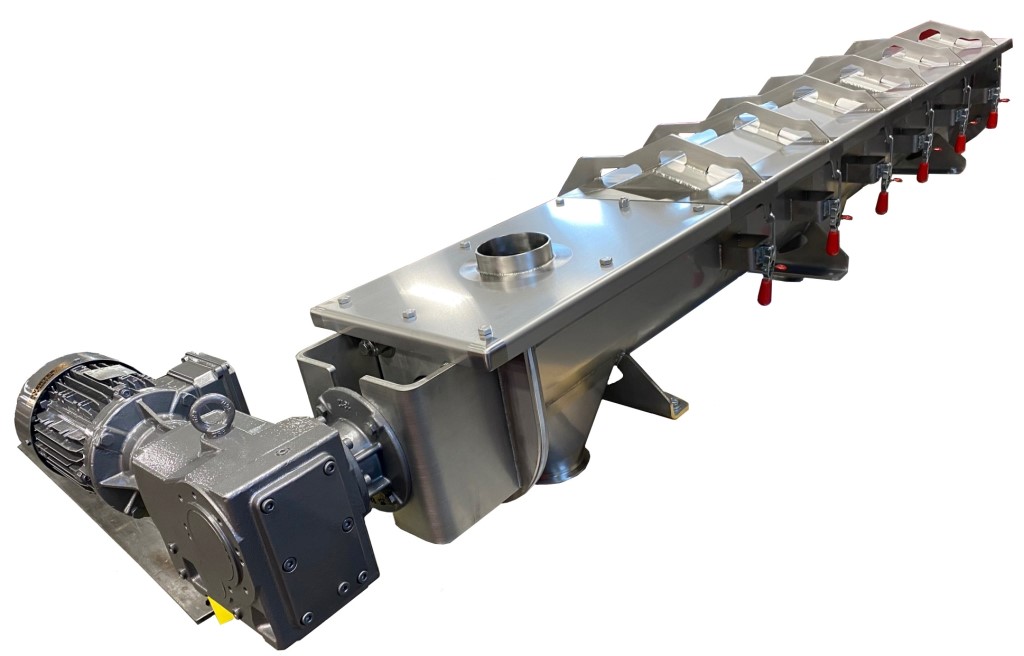

Tube- and trough-style auger systems.

Screw conveyor systems can offer a wide range of designs and materials. We design a tube- and trough-style auger system to CEMA standards. We can meet your needs from heavy-duty abrasive handling to high-finish stainless steel USDA requirements including designs that can be easily disassembled for cleaning.

A screw feeder uses a rotating helical screw blade, called a flighting, usually within a tube to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, and many others.

They usually consist of a trough or tube containing either a spiral blade coiled around a shaft or driven at one end and held at the other. The rate of volume transfer is proportional to the rotation rate of the shaft. In industrial control applications, the device is often used as a variable rate feeder by varying the rotation rate of the shaft to deliver a measured rate or quantity of material into a process.

Screw conveyors can be operated with the flow of material inclined upward. When space allows, this is a very economical method of elevating and conveying. As the angle of inclination increases, the capacity of a given unit rapidly decreases. The rotating part of the conveyor is sometimes called simply augers.