Gates and diverters – the right solutions

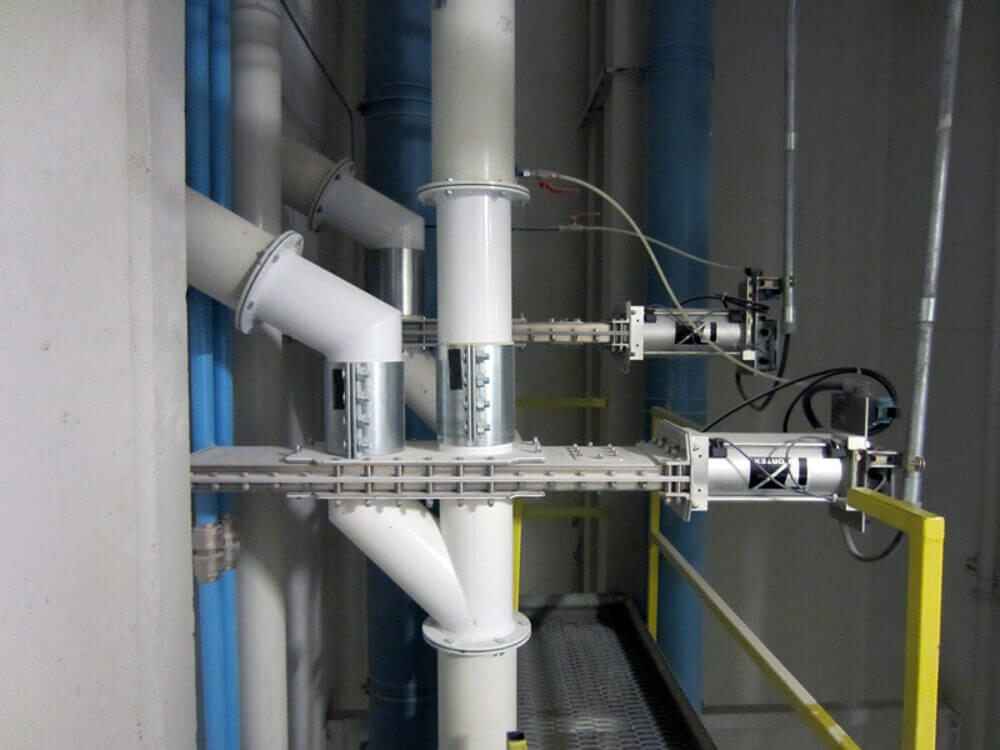

Gates and diverters are ideal for handling dry bulk material in gravity flow, dilute phase, or dense phase pneumatic conveying applications. Valves are used to shut off, meter, and divert dry bulk material. Common gates include orifice gates, roller gates, wye line diverters, flop gates, flex tube diverters, aggregate diverters, hand slide gates, maintenance gates, and iris valves. Valves can be constructed from heavy-duty carbon steel for abrasive applications to polished stainless steel for food applications. Valves can be actuated by hand, pneumatic, or hydraulic cylinders or electric actuators.

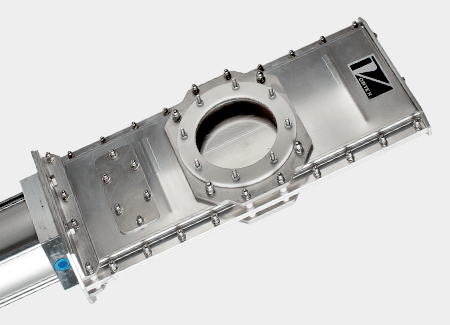

Vortex Quantum Series

Vortex Quantum Series slide gates and diverters are the valves our customers have been using for decades to shut off, meter, and divert their dry bulk material. It’s our traditional line of valves for dry bulk processing and conveying through gravity flow or pneumatic (pressure or vacuum) conveying. Some of the industries that use Vortex Quantum valves include but are not limited to: agriculture, chemical, coffee, dairy, foods, milling, pet food, petrochemical, pharmaceutical, plastics, rubber, textiles, tobacco, and wood.

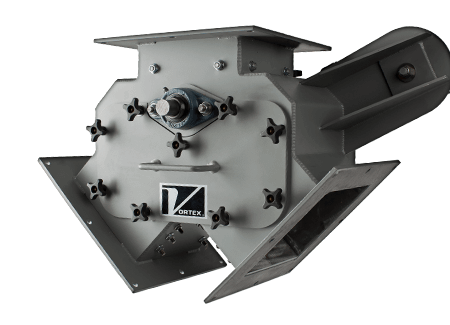

Vortex Titan Series

Vortex Titan Series slide gates and diverters are valves that are engineered for heavy-duty material handling applications that pose additional abrasion or wear issues. This series also covers pneumatic conveying (pressure or vacuum) and gravity flow material handling. Some of the materials handled with Vortex Titan valves include but are not limited to: alumina, bauxite, cement, clinker, coal, fly ash, frac sand, gravel, glass cullet, lime/limestone, metal powders, and potash.