Dynequip filter receivers – a step above the rest.

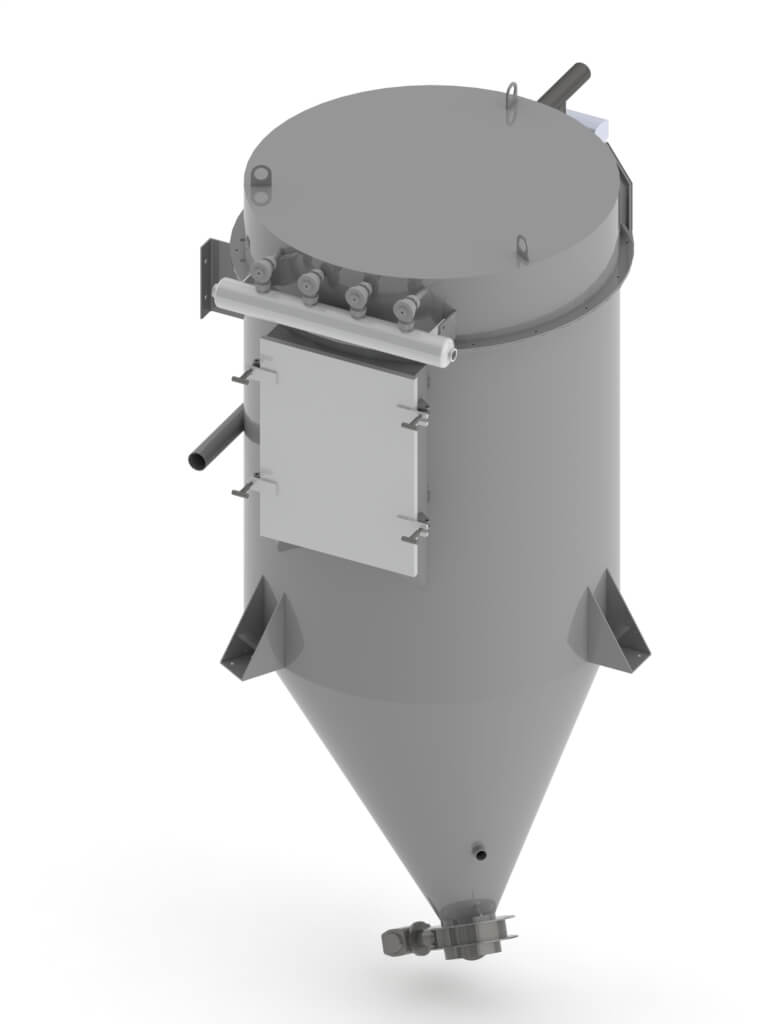

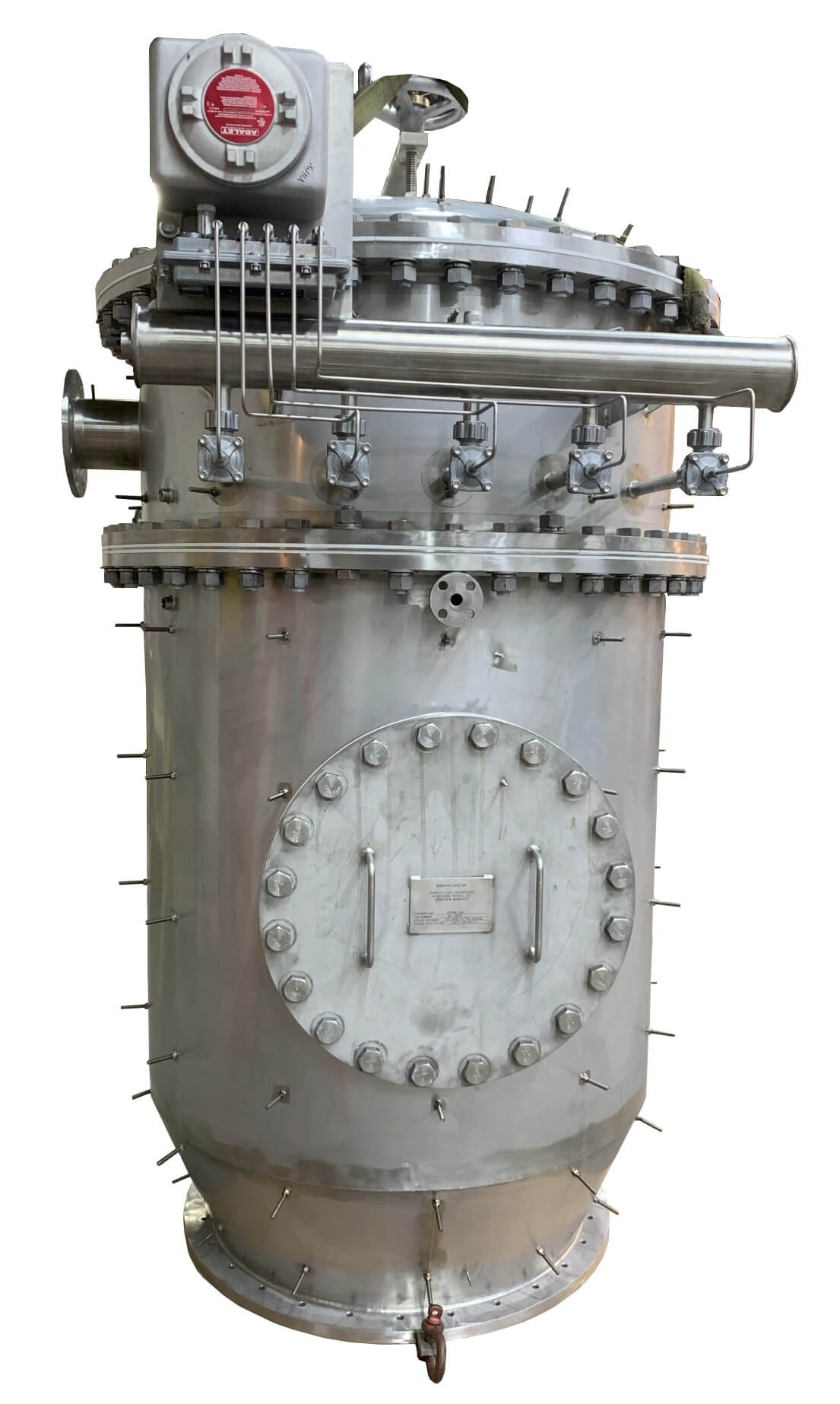

A filter receiver is a specific application of a dust collector used to separate product from air in a pneumatic convey system where product is moved from one point in a facility to another. Dilute or dense phase pressure and vacuum systems all utilize similar equipment.

Filter receivers are often round/cylindrical to better handle the pressure of the vacuum they are used under. They can utilize a variety of filter medias and designs but most commonly use long, narrow-sewn fabric filter socks or rigid, pleated, filter element cartridges. Industrial filter receivers are often made from carbon steel where a food facility might want polished stainless steel.

Filter receivers are normally self-cleaning. Self-cleaning systems include reverse-pulsed air (briefly running air backward through the filter to remove dust) and “shakers” that physically shake the dust off.