The uses for soda ash in water treatment systems is vast. The addition of this powdery substance is used to adjust pH levels in water to either raise or lower it, so it comes to a more neutral state. The same soda ash is frequently used in wastewater treatment plants to neutralize acidic wastewater before discharging it into water bodies. This process helps to prevent adverse effects of wastewater on aquatic ecosystems.

Moving powdery substances such as soda ash can pose several dangers if not managed properly that could include dust explosion, fire hazard, and health risks to workers and more.

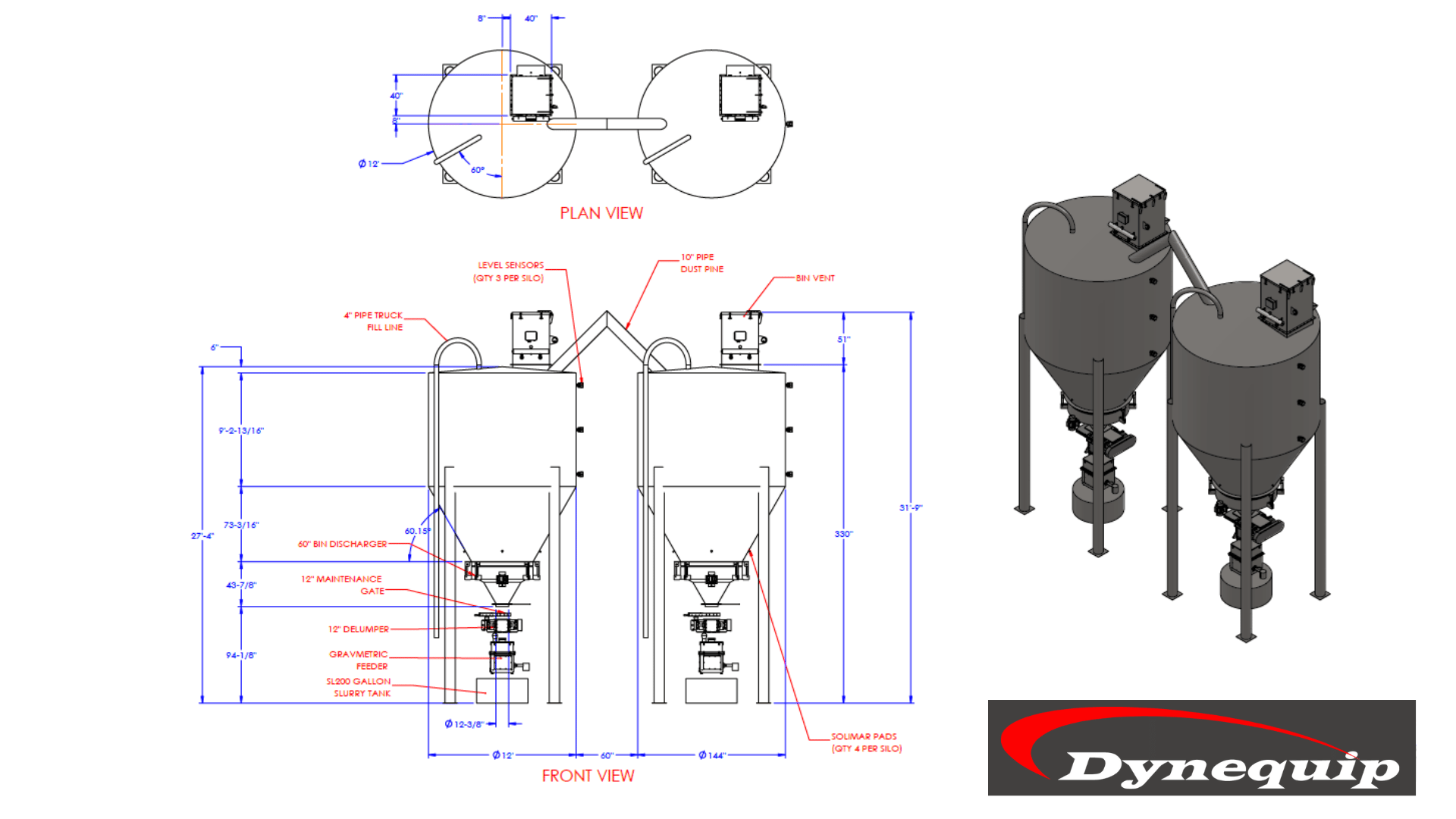

Dynequip specializes in managing the proper way to move bulk materials like soda ash in water facilities. Our engineers are experts in creating customs systems that supply complete material handling and processing solutions to our customers. While no systems we create are the same, many of the components in them are.

Powdery substance handling, like soda ash, may incorporates components such as:

Bin Vents – A bin vent, sometimes known as a dust collector or dust filter, is essential in a system the incorporates a silo. The main function of a bin vent is to prevent the release of dust and particulate matter into the air during the filling and emptying process of the silo.

Tecweigh Gravimetric Feeders – A techweigh gravimetric feeder is a precision instrument used to accurately dispense and control the flow of bulk materials based on weight. This type of feeder is often used in the batching and blending process when accurate measurement and control of quantity is important.

Silo Hoppers/ Carmen Bin Dischargers – Designed to improve the flow characteristics of bulk materials stored in silos or hoppers, these components help prevent material bridging, rat-holing, and arching, which can lead to flow interruptions and inefficient material discharge.

Vortex Maintenance Gates – These gates provide reliable shut-off and control of material flow in gravity-fed or pneumatic conveying systems.

Flex Augers – A versatile and efficient solution for bulk material handling that is gentle and easy to maintain.

Check out the diagrams below to see some of the most recent systems we have built for the water treatment industry. Do you have a project you need help executing? Our experts are available to talk with you about your needs and how we can build the right system for your facility.