Dynequip is the local representative of Vortex, a solids & bulk handling components company based in Salina, Kansas. We are very appreciative of our long-lasting partnership, so we want to highlight some of the great work they do and material handling solutions they offer. Vortex will be visiting the Minneapolis and St. Paul area from May 16-30 and June 1-3 with their display van, so please reach out if you would like to set up a visit. Vortex offers a wide range of valves, including:

- Slide Gates—Used to control the flow of bulk material in gravity flow, this variety of gates serve industries like cement, food, minerals, plastics, and more. Vortex offers twelve different Slide Gate products, all designed to extend the life of the valve.

- Roller Gates—This type of slide gate is a great solution for handling and moving dry material in low-pressure applications. Unlike similar slide gates with rubber or felt seals, its seals are stronger and can extend the life of the product.

- Iris Valves—This valve from their Quantum Series opens and closes towards the middle of the opening to restrict materials or allow them to flow gradually from bins, bulk bags, chutes, or hoppers. The fabric sleeve and slower closing action prevents delicate materials from breaking or deteriorating.

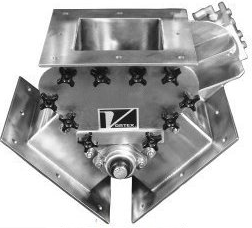

- Diverter Valves—Vortex has a number of diverter valves including an Aggregate Diverter, Seal Tite Diverter, Flex Tube Diverter, and more, each of them designed to suit different needs of various industries.

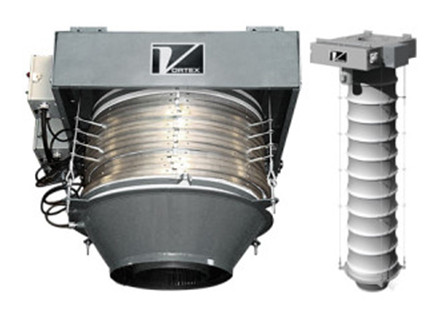

- Load-Out Spouts—The spouts that Vortex produces are designed to capture dust and prevent material waste during the loading process. Their load-out spouts move material quickly and are ideal for truck, railcar, and barge loading applications.

Below are images of the Vortex Orifice Gate, the Seal Tite Diverter Valve, and the Load-Out Spout. If you have any questions or would like to discuss any of the Vortex handling solutions, please give us a call. Again, if you would like to arrange a visit with Vortex from May 16-30 and June 1-3, let us know.