Dynequip builds custom systems for all types of manufacturing and material processing businesses. This month we’re featuring a few of our recent custom builds.

HOIST LOADED BULK BAG UNLOADER

HOIST LOADED BULK BAG UNLOADERIn this build, we feature the lower section of a hoist loaded bulk bag unloader. This fed a horizontal flex auger. You’ll notice the bag bottom paddles do not actuate. This was done because the product intended for the unloader is free-flowing. The unit features an Iris Valve over a round stainless steel tie-box as well.

CARBON STEEL BAG DUMP STATION

The carbon steel bag dump station featured at right was custom built per our customer’s specifications. You’ll notice a “stub” was incorporated into the design to accommodate their existing dust collection system. The collapsible front bag tray and internal bag grate were customized per the specs given. This bag dump station can feed flex augers, rotary airlocks or any other part of the process.

The carbon steel bag dump station featured at right was custom built per our customer’s specifications. You’ll notice a “stub” was incorporated into the design to accommodate their existing dust collection system. The collapsible front bag tray and internal bag grate were customized per the specs given. This bag dump station can feed flex augers, rotary airlocks or any other part of the process.SHALLOW INCLINE FLEX AUGER

This Shallow Incline Flex Auger was built to receive product from screening. It’s equipped with a carbon steel outer tube and a pusher style drive.

This Shallow Incline Flex Auger was built to receive product from screening. It’s equipped with a carbon steel outer tube and a pusher style drive.HIGH-TEMP FILTER RECEIVER

This custom piece is a high-temp filter receiver featuring stainless steel construction with heavy flanges. It is jacketed for steam or hot oil tempering.

This custom piece is a high-temp filter receiver featuring stainless steel construction with heavy flanges. It is jacketed for steam or hot oil tempering.HEMP HOPPER, CONVEYOR AND BAGGING SYSTEM

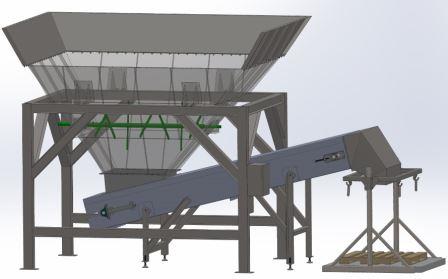

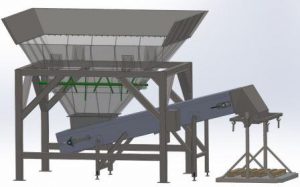

Dynequip builds many custom systems for the growing hemp industry. The hopper featured here is in process. You can see in the CAD model, it is filled by a front-end loader and will fill super sacks.The hopper has the ability to agitate and has an inclined and cleated belt conveyor. It is also a scaling system.

Dynequip builds many custom systems for the growing hemp industry. The hopper featured here is in process. You can see in the CAD model, it is filled by a front-end loader and will fill super sacks.The hopper has the ability to agitate and has an inclined and cleated belt conveyor. It is also a scaling system.