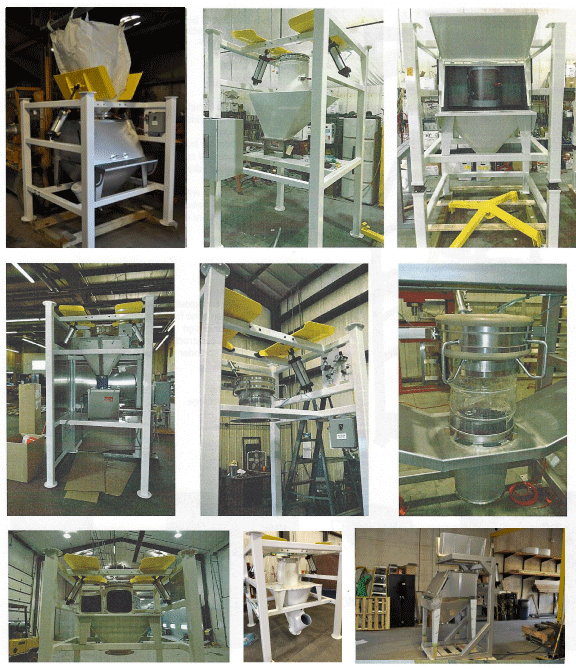

Our bulk bag unloading systems accommodate all from bulk bags to totes and large to small bag adjustability.

Our bulk bag unloaders provide a dependable method of unloading bagged bulk and semi-bulk materials. The system can easily be operated or serviced by one person and is a cost-effective solution to bulk bag handling operations.

Bulk Bag Unloader/Hoist Series 5000

Dynequip series 5000 bulk bag unloaders are used to unload super sack bags of material (granular or powders)

for a variety of system applications.

These machines have some great features! They include but are not limited to:

- Heavy duty all welded tube construction

- Bag agitation

- Spreader bars for bulk bag support

- Hand operated air control panel

- Hoist w/ pendant drop

- Iris valve

- Confinement box with door

- Powder coated frame (foot print 60″ square)

- Frames heights are engineered to suit customer specified bag sizes

- 5 CUFT hopper

We have optional features too!

- Air inflatable bag spout connection (traveling and fixed)

- One or two ton hoist frame designs

- Open member design

- 304SS/316SS construction/food grade

- Certified bag spreader arms with load tested certificate

- Portable stairs

- Level controls

- Hopper aeration

- Bag dump discharge

- Load cells

- Dust collection

Inflatable Spout

Inflatable Spout- Fixed

- Traveling

Iris Valve with Confinement Box

- Door access